Plasma sources for surface treatment of different materials

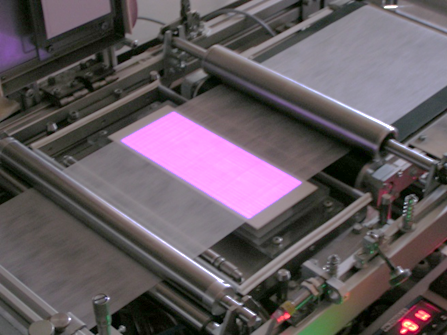

- Diffuse Coplanar Surface Barrier Discharge (DCSBD)

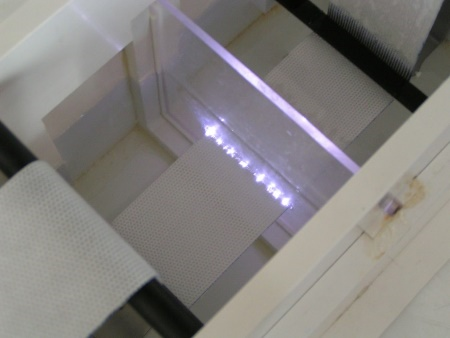

- Prototype ZUP200 for plasma treatment of nonwoven textile

- Diaphragm pulse discharge generating plasma in liquids

- Heated plasma reactor with DCSBD generating plasma in pure water vapor

- Experimental set-up for plasma polymerization

|

|

| Fig. 1. Low temperature DCSBD plasma |

Fig. 2. Device ZUP 200 for continuous plasma activation of narrow strips of thin materials – textiles. * The device was developed in the frame of |

Fig. 3. Diaphragm pulse discharge generating plasma in liquids

Research areas

- Breakdown mechanisms in water discharge and plasma generation by the electric pulsed diaphragm discharge in a liquid medium using electrical and optical measurements

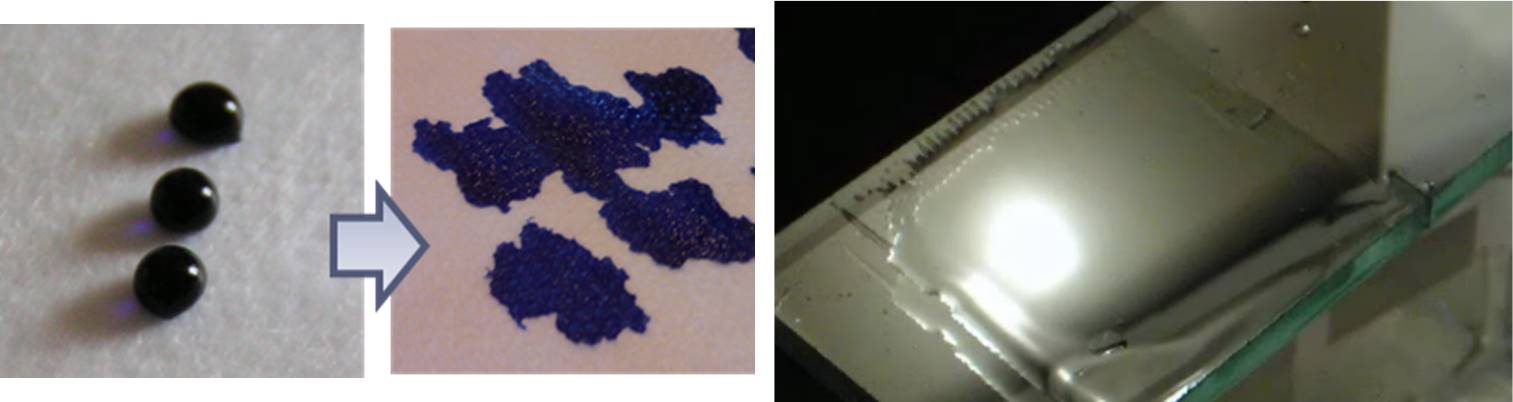

- The changes on surface of the polymeric material treated by non-equilibrium plasma generated in the liquid medium using suitable surface diagnostic methods

- Surface modifications of different materials after non-equilibrium plasma generated in ambient air (N2, CO2, O2) treatment using suitable surface diagnostic methods (wettability, adhesion properties, ageing)

- Materials: nonwoven textile, polymers (PP,PET, PTFE, PMMA, PLA, etc.), glass, metals, oxides of metals, wood, silicon wafers and others

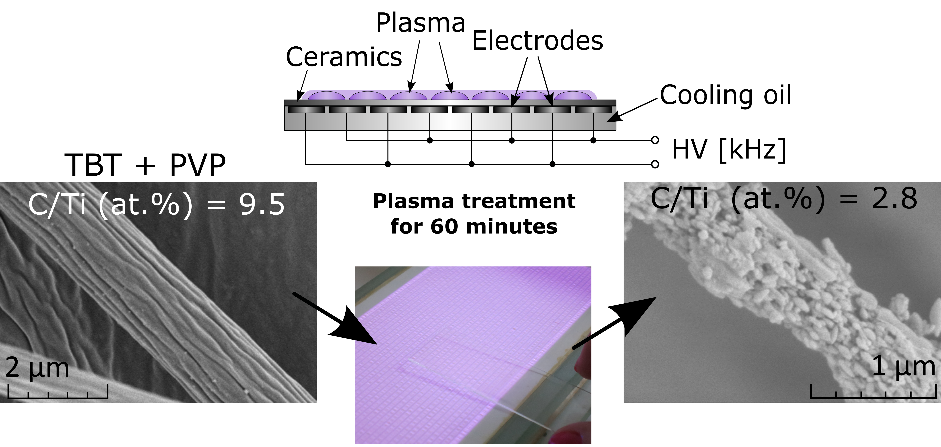

- Preparation of inorganic nanofibers (TiO2, Al2O3, CeO2, ZnO, ZrO2, etc.) from polymer template technique using low temperature plasma as an alternative to conventional thermal calcination

|

|

|

| Fig. 4. Significant increase of wettability of polymer textiles after short plasma treatment (in the order of seconds) |

Fig. 5. Cleaning and increase of surface energy of common glass and special glasses (ITO glass used in semiconductor industry |

Fig. 6. Improvement of adhesion of non-adhesive polymers (teflon) for further surface modification

Fig. 7. Plasma assisted calcination of inorganic nanofibers using DCSBD

Plasma diagnostics methods:

- Measurement of electrical parameters using current probe (Pearson Electronics Model 6600) and high voltage probe (type VD-100, 10000:1, High Voltage Products GmbH) together with digital oscilloscope (Agilent, DSOX3052A, 500 MHz, 4GSa/s) for accurate recording of the shape of discharge pulses.

- Study of fast processes associated with formation of the discharge by means of high-speed camera (type pgo.1200s, PCO A.G.)

- Optical diagnostics of plasmas by means of optical emission spectroscopy: UV-VIS spectrometer (Ocean Optics, USB2000), spectrometer Avantes,

- Investigation of effect of gases dissolved in form of bubbles in the reaction chamber on discharge ignition and plasma generation.

Diagnostics of changes on the surface of material:

- Evaluation of surface energy changes of plasma treated surfaces by means of the contact angle measurement (See System, Krüss DSA 30).

- The study of surface morphology (SEM, AFM)

- Elemental analysis (EDX, WDX)

- The characterization of chemical bonds present on surfaces of plasma treated materials FTIR

- Chemical composition of surface layer that corresponds to about 10 atomic layers (XPS)

Collaboration with:

- VÚTCH-CHEMITEX spol. s r.o., Žilina

- Pardam Nanotechnology, s.r.o., Czech Republic

- Singapore Institute of Manufacturing Technology

- Polymer Institute SAS, Bratislava

- Institute of Materials Research SASm Košice

- Faculty of Chemical and Food Technology STU, Bratislava

- Faculty of Science, Masaryk University, Brno

- University of Innsbruck

- Swiss Federal Laboratories for Materials Science and Technology, EMPA, Switzerland

Contact:

Doc. RNDr. Anna Zahoranová, PhD.

F2-40

Email: zahoranova(at)fmph.uniba.sk

Phone Nr: +421 2 602 95 529

Mgr. Dušan Kováčik, PhD.

F2-37

Email: kovacik(at)fmph.uniba.sk

Phone Nr: +421 2 602 95 616